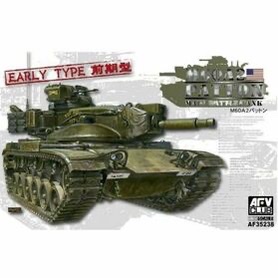

- Purchased: 2020

Built: 2020

Enhancements: Tracks: AFV Club

MG Barrel: Master barrel Headlights: SKP Model

Antenna bases: Voyager

I’ve always loved these cold war tanks, the M60A2 having a rather uniquely shaped turret which added to the appeal.

Reviews on line painted a rather good picture of AFV Club’s kit too, although its not a kit I’ve seen built often.

The AFV Club kit is moulded in an olive drab plastic, the many sprues filling the box to the brim. An aluminium main gun barrel, PE mesh and detail parts, string tow cables, clear parts for the periscopes also round out the package. Tracks are of the rubber band variety, the main gun and machine gun dust covers are provided in a vinyl type material. The armour version of an Eduard Profipack kit, although this seems to be a standard of all AFV Club kits.

Once construction is commenced though, you realise a lot of the parts are not needed as they apply to other variants of the M60 family. Although AFVC also offer a late type M60A2, I imagine you could also build one from this boxing as they include the later type wheels and air intakes. You might need different tracks.

The build seemed to go on for ever, mainly due to having to clean up a faint mould seam on all parts, which started to become tedious, especially on the small parts and certainly took away some of the enjoyment.

I ended up breaking some of the turret basket rails whilst doing this so replaced the broken parts with brass and plastic rod. I not sure I got it all square though.

A Master Details brass barrel replaced the plastic M85 barrel provided by AFVC, and I replaced the kit provided tow cables with some copper ones I found in my spares box, and she was ready for painting.